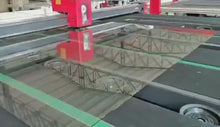

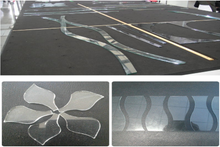

This set of equipment is the latest development , which is including loading, taking glass, straight cutting,shape cutting, air flotation, breaking, automatically move and walk (around), remote control. It is currently the most advanced automatic glass

cutting system, instead of the traditional automatic glass cutting line(loading table, cutting machine, breaking table).It is significantly reduce the labor intensity of workers, with convenient operation, low investment and benefit advantages, greatly

reducing the cost, it is the best choice for small and medium enterprise

|

The Diemension |

4200*3800*900mm |

|

The cutting speed |

150m/minute(can be adjustable) |

|

The cutting accuracy |

Parallelism:≤±0.15mm/m |

|

Cutting size |

3660*2440mm |

|

Thickness |

3-19mm |

|

Max sucking depth |

700mm |

|

Max glass weight |

900 kgs |

|

The transportation device |

It adopt Flotation device which makes it. |

|

The oiling supply method |

Auto oiling. |

|

Transmission system |

The X,Y,Z Axis are equipped with reliable motor. |

|

Arm quantity |

3 pcs |

|

Brand name |

Eworld |

|

Sucker quantity |

9/12 pcs |

|

Loading arm type |

single poisition,one side. |

|

Sucker quantity |

9/12 pcs |

|

Power |

6 kw |

|

Air consuption |

0.3Mpa |

|

Vacuum pressure |

70-90Kpa |

|

Cutting speed |

150m/min |

|

Power supply |

380V/220V/Customized |

|

Brand name |

Eworld |

|

Working method |

CNC full automatic |

|

Cutter |

Germany |

|

Motor |

Yaskawa Japan |

|

The cutter block |

It adopt pneumatic and spring at the same time. |

|

Automatic glass edge testing |

Yes |

|

Optimization |

Yes |

You may also like

-

small size cnc glass cutting machine glass cnc cutter 4x4ft

![small size cnc glass cutting machine glass cnc cutter 4x4ft - OSAIN CNC Router]()

- Prix normal

- $5,600.00

- Prix réduit

- $5,600.00

- Prix normal

-

$6,500.00 - Prix unitaire

- par

Épuisé -

3axis CNC Plasma Cutting Machine

![3axis CNC Plasma Cutting Machine - OSAIN CNC Router]()

- Prix normal

- $6,500.00

- Prix réduit

- $6,500.00

- Prix normal

-

$9,000.00 - Prix unitaire

- par

Épuisé -

CNC Glass Machine for edge grinding and polishing

![CNC Glass Machine for edge grinding and polishing - OSAIN CNC Router]()

- Prix normal

- $28,500.00

- Prix réduit

- $28,500.00

- Prix normal

-

$38,500.00 - Prix unitaire

- par

Épuisé -

200X150mm benchtop cnc mill diy cnc milling machine free shipping by sea

![200X150mm benchtop cnc mill diy cnc milling machine free shipping by sea - OSAIN CNC Router]()

- Prix normal

- $5,850.00

- Prix réduit

- $5,850.00

- Prix normal

-

$5,850.00 - Prix unitaire

- par

Épuisé